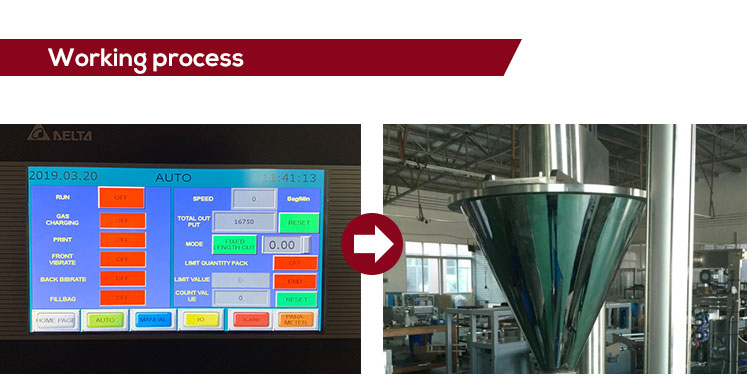

1. Imported PLC control system and color touching screen enable easy and efficient operation

2. The bag type is diversified, and it can provide customers with pillow-shopped bags, gusset bags, hanging hole bags, and even bags

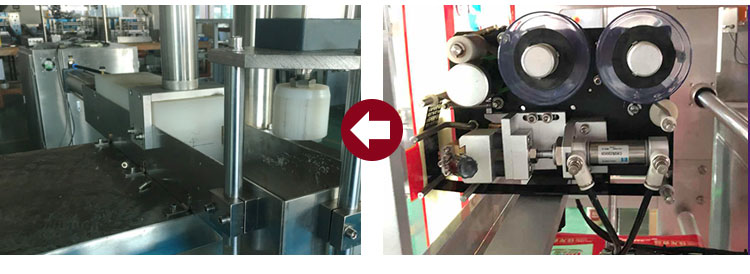

3. Imported servo film transport system, imported color standard sensor, accurate positioning, excellent machine performance, and beautiful packaging

4. A variety of automatic alarm protection functions are used to minimize losses

This is an integrated producing line, which is widely adopted in Tobacco Honey processing scope, achieved complete procedure of bag forming, filling, sealing, cartooning as well as cellophane overwrapping, with high efficiency and perfect packing effect.

| Measurement Range | 150~1500ml |

| Packing Size | L: 80-300mm W: 60-200mm |

| Packaging Speed | 30~80bags/min |

| Machine Size | (L)1350*(W)10150*(H)1343mm |

| Machine Weight | 550KG |

Sealing Style | Back sealing |

| Cutting | Tooth Cut / Flat Cut |

| Power | 220V, 50HZ, 2.2KVA |

1st step: Setting the parameters you want by touch screen

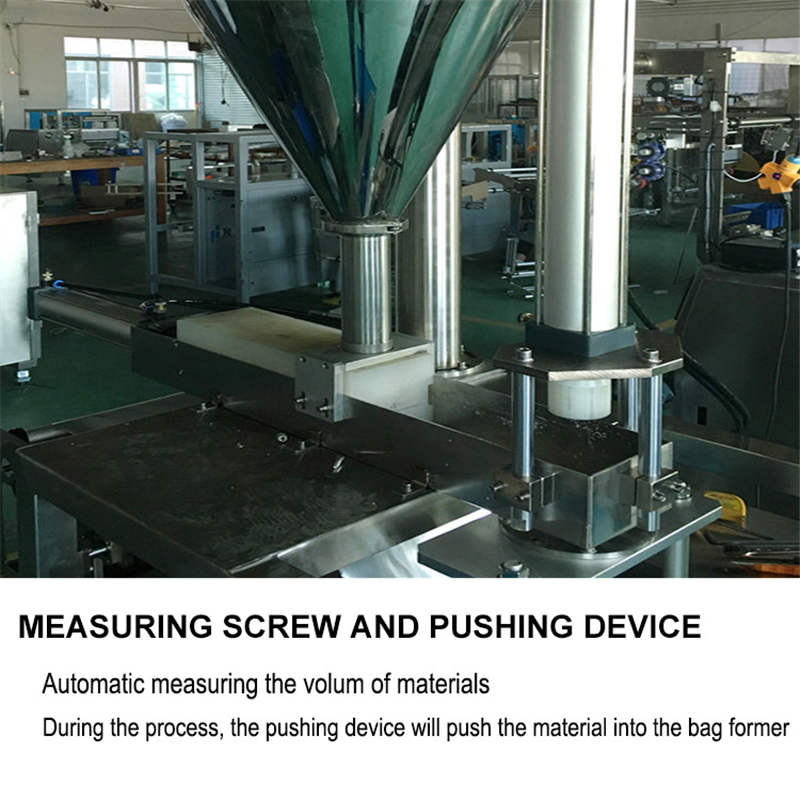

2nd step: Put the material into the stainless hopper

3rd step: Metering screw - Automatic measuring the Shisha Tobacco

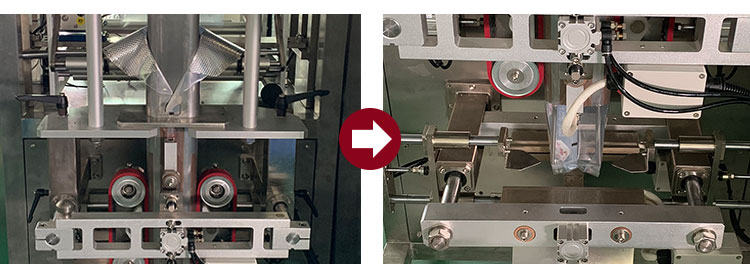

4th step: The bag former will make the bag automatically

5th step: The horizontal and vertical cutter device will seal the middle and the end of the bag

6th step: You will get the nicely paper or plastic bag type

Electrical configuration